Projects

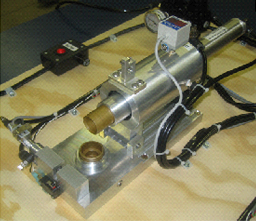

Swage Form Press – Engineering, CAD Design, CNC Machining and Assembly

One of our manufacturing clients had several swage form machines that were created internally and not standardized. Since there was no documentation, IEM encouraged the client to reverse engineer the entire machine and made several design improvements along the way.

Once the machine was documented, IEM won the bid to build four new machines. The client was very happy that their manufacturing tolerances were less than half the range of the other machines. Now they run all of their tight tolerance work on the IEM built presses!

“Inventure Engineering & Machine is a valued and trusted source for our product offering. We work with companies and institutions involved in and around research for Semiconductor, Nanotechnology, MEMS Device Manufacturing, Solar PV and Flat Panel Display. These cutting edge technologies come to us with a large variety of applications that seldom have "off the shelf" solutions. IEM has been there with good engineering practices and principles that has helped us identify fundamental solutions. What IEM truly offers us is an engineering extension of our company. They care about the results of our products and have the background and experience to support us.”

Ted Jones, Critical Systems, Inc.

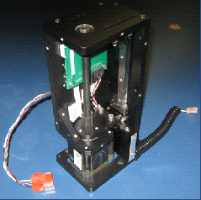

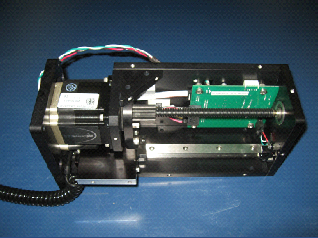

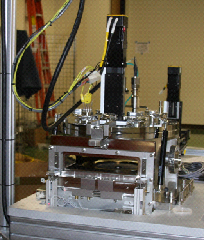

Wafer Cassette Elevator – Engineering, CAD Design, CNC Machining, Electrical, Software Programming and Assembly

Semiconductor equipment OEM was struggling to find a replacement wafer boat elevator as their current unit was no longer being produced. IEM created a new design utilizing modern components and control architecture, while still maintaining the fit, form and function of the original unit. This resulting elevator is a direct bolt in replacement with 'plug and play' interface to the original machine.

"Inventure Engineering & Machine was recommended to me by one of my vendors. He mentioned that they have very talented and experienced engineers that might be able to help our company. IEM was able to help me build our product to better serve our customers. IEM asked very specific questions that allowed them to come up with the best solution at a great price. They were very professional and we felt that the engineering cost was very reasonable. The first project was a success, so we have called them back to work on more."

Mark Montgomery, General Manager, Analogee, LLC

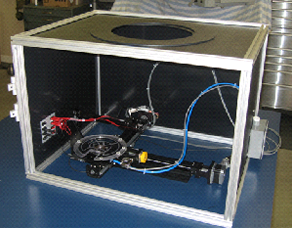

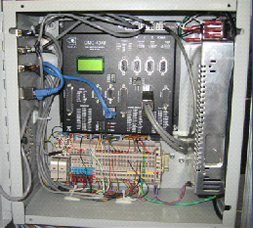

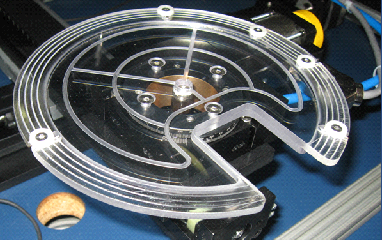

Solar Simulator Automation – Engineering, CAD Design, CNC Machining, Electrical, Software Programming and Assembly

Startup company pursuing a better way to manufacture photovoltaic (PV) solar wafers needed an automated test station to measure the performance of their solar cells. This machine involved four automated axis (X, Y, Z, Θ) and would automatically scan all cells on each silicon wafer in a controlled environment. A horizontal arm (capable of Z axis motion) held an array of pogo pins that established electrical communication with each solar cell, after being pre-positioned by the (X, Y, Θ) axis.

"Inventure Engineering & Machine has been a ray of sunshine in the Treasure Valley for us. We have used several other vendors around town but the personable, friendly service that you get with Inventure Engineering sets them apart from all others. You aren’t just another dollar sign in their books, you are a valuable customer and Tony is hands on and extremely reliable. His timing, pricing and expertise are a step above the rest. Inventure Engineering is willing to sit with us and help us re-think designs that aren’t so successful, and come up with affordable ways to change things. Inventure Engineering is a local business that will treat you as a neighbor and ensure that things are right for you. I highly recommend them to any future customer. Thanks Tony for everything you do for us."

Debbie S., nextScan, Inc

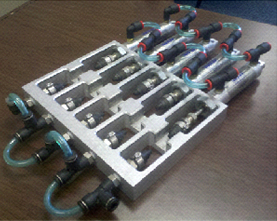

Assembly and Test Equipment – Engineering, CAD Design, CNC Machining and Assembly

Manufacturer of plumbing products frequently needs equipment to assist with assembly and/or testing of their products. IEM will meet with the client to understand their desired outcome and test criteria then go to work with 3D CAD design. Once complete, the design is reviewed with the

client and once approved; the finished assembly is built and tested.

"We were looking for an engineer to help us with some of our in house projects. Upon meeting Tony and working with him we would highly recommend him to anyone. Inventure Engineering took our company to the next level. Tony is very easy to work with and understands our needs. He thinks outside the box, and not only recommends things but also listens to our needs and finds the best fit. Inventure Engineering & Machine has very high quality work and very tight tolerances. They also get our projects done in a timely manner. We would highly recommend Inventure Engineering to anyone that is seeking a great company to work with.”

Steve Stradley, General Manager Accura Bullets

Semiconductor and Solar Equipment – Engineering,CAD Design, CNC Machining, Electrical, Software Programming and Assembly

Several semiconductor and solar cell manufactures have relied on IEM to assist with equipment and handling tools for many years. Projects included: diffusion furnace handling tools, custom LED light

assemblies, metering pump attachments, fabricated plastic weldments, custom valves, etc. IEM has worked with a variety of materials including exotic plastics, ceramics and metals.

"We were referred to Tony and Inventure Engineering & Machine (IEM) from another, larger machining/fabricating organization. Since that time Tony has proven to be a valuable asset, and a personal friendship has developed as a result of the business connection. There has not been a time when the IEM Team could not get the job done, and the level of professionalism and product quality are second to none. Inventure Engineering will be an asset to any organization, and I encourage anyone to try their machining/CNC/engineering services.”

John Aleman, Commercial Printer